480-899-9089

480-899-9089

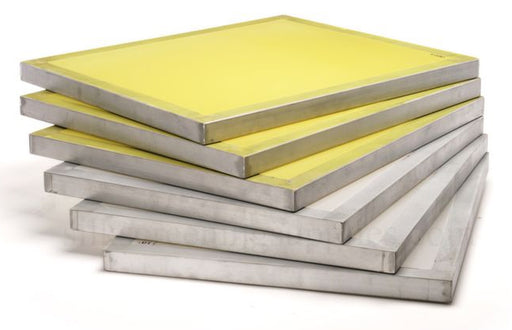

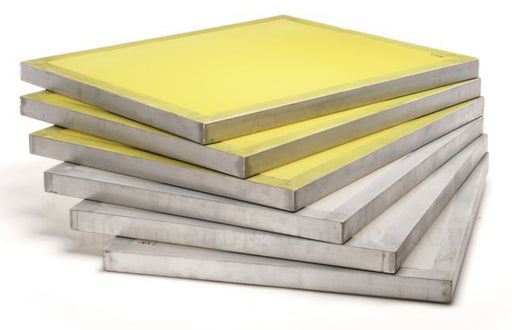

Pre-stretched screen printing screens for screenprinting. These are 20x24 manual and 23x31 automatic metal screen printing screens. These are pre-stretched with mesh and ready to be prepped for screen making. These will have tight mesh tensions between 18 to 20 Newtons. Make sure to use a rigid screen when printing tee shirts. Metal screens are more reliable for tight registration printing. They do not warp, never get weak at the corners and they can hold a higher mesh tension.

Our aluminum frames are cut from 6005T5 alloy, pulse welded securely to insure a water tight seal, and ground smooth for flatness and handling ease. Our screens are assembled and/or made in the USA.

Manual Screens Automatic Screens

Use a 28 to 30 mesh count for printing many brands glitter inks. Always check with the manufacturer of the ink about this. This mesh will print a very high volume of ink and have a thick coat of emulsion making it difficult to expose.

Use an 85 mesh count for athletic printing, opaque ink deposits, thick puff ink, and some shimmer inks. This mesh will print a very high volume of ink and have a thick coat of emulsion making it difficult to expose.

Use a 110 mesh count for heavy coverage on dark shirts, solid under base prints, puff, metallic, some shimmer inks, and for certain transfer printing. This is a great mesh count for high opacity inks on any dark garments.

Use a 155 or 160 mesh count for general printing on white tee shirts & under basing on dark shirts, prints on nylon jackets, and thinner silver shimmer inks. Many thinner plastisol inks will print well with this mesh count.

Use a 195 mesh count for printing on light colored T-shirts with fine detail, line work or halftones of around 35 LPI.

Use a 230 mesh count for printing on light colored tee shirts with fine detail, line work or halftones of around 45 LPI.

Use a 305 to 355 mesh count for process color on light shirts, or for overprinting a halftone on a white under base on dark shirts. You should be able to pull of halftones of up to 65 LPI but a 55 LPI is most common.

Most lower mesh counts will always be colored white. Dyed or yellow mesh starts at about 200 mesh and higher. If you have been using a 156 or 160 mesh count or lower that is yellow or amber in color, that is a specially dyed mesh and is not normal to find.

Our mesh is dyed as follows:

25, 110, 125, 156, 160 = WHITE

200, 230, 305, 355 = YELLOW

Sold out

Sold out

WHITE MESH (6 pack) Pre-stretched 110 mesh screens for screenprinting tee shirts. This is a mesh count used for printing most basic spot colors wit...

View full details Sold out

Sold out

YELLOW MESH (6 Pack) - Pre-stretched 230 mesh for screenprinting tee shirts. This is a screen used for printing higher detailed designs including 1...

View full details Sold out

Sold out

YELLOW MESH (6 Pack) - Pre-stretched 200 mesh for screenprinting tee shirts. This is a screen used for printing higher detailed designs including 1...

View full details Sold out

Sold out

YELLOW MESH (6 Pack) - Pre-stretched 305 mesh for screenprinting tee shirts. This is a screen used for printing the highest detailed work such as C...

View full details Sold out

Sold out

WHITE MESH (6 pack) Pre-stretched 135 mesh for screenprinting tee shirts. This is a screen used for printing most basic spot colors with some detai...

View full details Sale

Sale

RhinoStretch™ Manual Screen Stretcher RSP200 - Table Top Manual Bar Stretcher, frames up to 23” x 31”. This unit offers enhanced warp and weft s...

View full details